Amazon.com: 7Magic Remanufactured Toner Cartridge Replacement for HP 305A 305X CE410X CE410A for HP Pro 400 Color MFP M451nw M451dn M451dw M475dw M475dn Pro 300 MFP M375nw M351A Printer (4 Pack) : Office Products

Printer HP LaserJet Pro 300 Color M351a มืิอสอง เลเซอร์สี พิมพ์เร็ว 18 แผ่น/นาที หมึกพร้อมใช้ - ปริ้นเตอร์มือสอง อะไหล่ printer รับประกันสินค้าทุกชิ้น พร้อมบริการ ติดตั้ง รับส่งฟรี (ทั่ว กทม.) : Inspired by LnwShop.com

Toner Bank 4-Pack Compatible Toner Cartridge Replacement for HP CE410X LaserJet Pro 400 Color M451dw M451dn 451nw M475dn Pro 300 Color MFP M375nw M351 Black, Cyan, Magenta, Yellow - Walmart.com

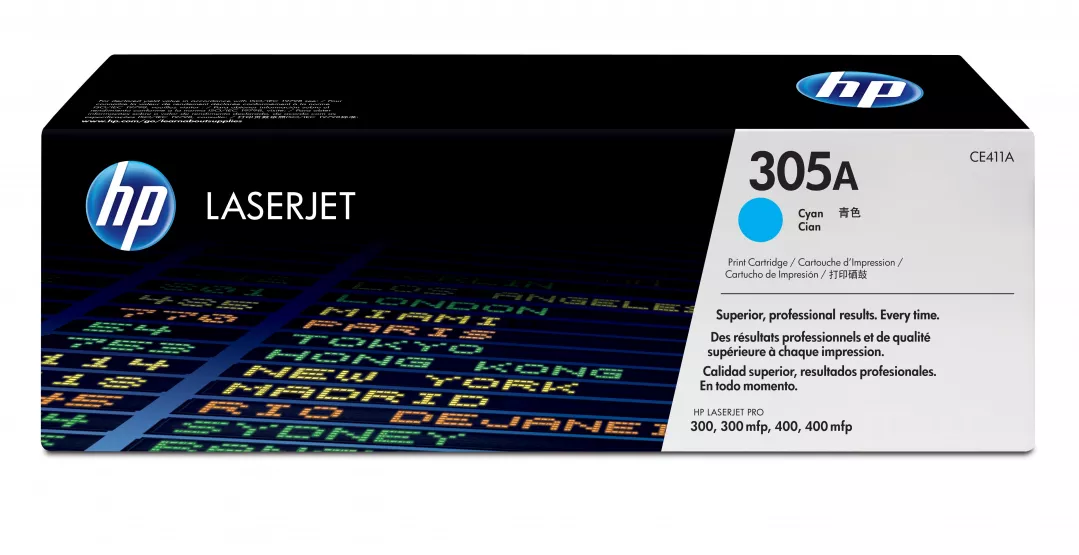

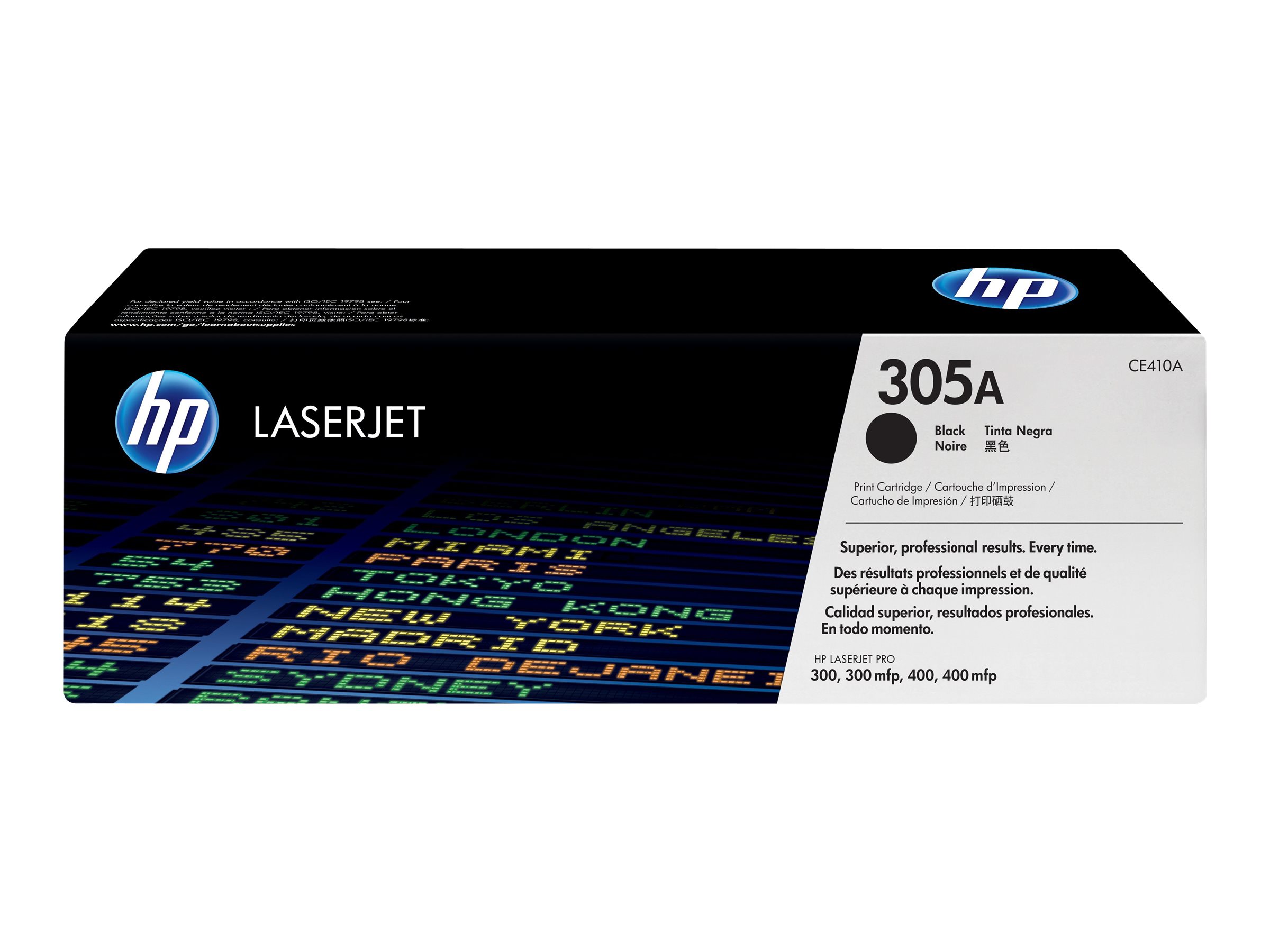

HP CE411A CE412A CE413A CF370AM 305A Toner Cartridge color LaserJet Pro 300 color MFP M375nw 400 M451 M451dn M451dw - Sun Data Supply

Amazon.com: HP 305A Black, Cyan, Magenta, Yellow Toner Cartridges (4-pack) | Works with LaserJet Pro 300 M351, LaserJet Pro 300 MFP M375, LaserJet Pro 400 M451, LaserJet Pro 400 MFP M475 | CE305AQ1 : Office Products